Industrial glue manufacturers share silicone glue for plastic bonding

Silicone adhesive: How do you choose? Exclusive DM agent in Shenzhen – a customized silicone adhesive manufacturer with a 70% higher viscosity than similar products. The success rate of bonding is as high as 99.9%, and the failure rate of bonding is as low as 0.001;

Adhesive is more efficient! DM. 5011 Instant Drying Adhesive Universal DM. 5011 Quick Drying Adhesive Technical Parameters: Chemical Matrix: Ethyl Positioning Time: Color: Transparent/Colorless Aluminum/Aluminum:> 500 seconds viscosity: 100 mPas SBR/SBR:< 5 seconds

Density: 1.06 g/cm3

PC:< 12 seconds

Temperature resistance range: -30 ℃ to+80 ℃ EPDM/EPDM:< 10 seconds

Melting point: 165 ℃

Tensile shear strength: Flash point: 87 ℃

Steel/Steel:> 20 N/mm2

Industrial glue manufacturers share silicone glue for plastic bonding

Shelf life: 12 months SBR/SBR: 1800 N Complete curing time: 24 hEPDM/EPDM: 280 N Certification: NSF DM. 5011 Instant Dry Adhesive Non Treatment Silicone Adhesive Series Professional for foaming silicone and silicone, silicone strip bonding, silicone and POM, silicone and engineering plastics, silicone and polyoxymethylene resin, silicone adhesive hard plastic, silicone and other plastics, silicone and metal, silicone and Velcro, TPR and Velcro, etc. The silicone surface does not require silicone treatment agent and can be directly coated with adhesive for bonding. Its bonding strength can reach the effect of tearing materials,

This adhesive has passed SGS certification and meets EU standards! DM. 5011 Instant Dry Adhesive Non Treatment Silicone Adhesive Series specializes in bonding foam silicone with silicone, silicone strips, silicone with other plastics such as PU leather (TPR, TPU, ABS, PC, PS, PVC, PP, BPT, EVA, POM Velcro, fabric, etc.), silicone with metals (stainless steel, tinplate, galvanized iron, aluminum alloy, aluminum tube, copper, etc.). The silicone surface does not require silicone treatment agent and can be directly coated with adhesive for quick positioning. Its bonding strength can reach the effect of tearing materials. This adhesive has passed SGS certification and meets EU standards! 【 Operation instructions for silicone adhesive plastic glue 】 The bonding surface must be clean and free of any contaminants such as dirt, oil stains, lubricants, and any products previously applied.

Before joining, lightly scratching the surface can achieve better results. We recommend using DM9195 cleaner for surface cleaning of glass and plastic, and DM9190 cleaner for metal. The silicone surface does not require treatment and can be directly coated with DM. 5011 instant dry silicone adhesive for bonding. The material coated with adhesive should be immediately adhered, and the adhesive should be positioned within 3-5 seconds, reaching the strength of the material after 3-5 minutes. After 24 hours, this product can be packaged or used.

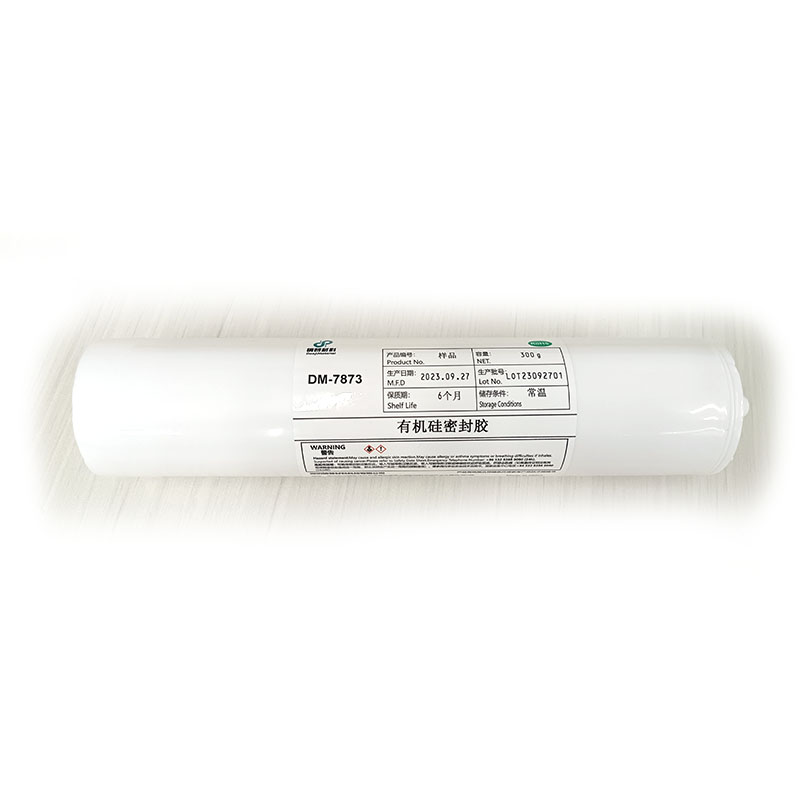

Silicone adhesive packaging specifications: 20ML/stick, 50ML/stick, can be packaged according to customer requirements. Storage method for silicone adhesive: Store the product in an unopened container in a cool and dry environment. The storage temperature ranges from+2 ℃ to 8 ℃. Under the above storage conditions, the shelf life varies from 6 to 12 months depending on the type of product. When removing the product from the refrigerated environment, allow the silicone adhesive, plastic adhesive, and bonding agent to reach room temperature before use.

Industrial glue manufacturers share silicone glue for plastic bonding

adhsive glue

Welcome new and old customers to call us for inquiries. We support small batch production and customized appearance. We will provide you with 1V1 technical consulting services for free! We have a research and development center of over 3000 square meters in Shenzhen Guangming Pilot Industrial Base, with 12+laboratories. We welcome new and old customers to inquire by phone. Our company supports small batch customization and packaging design,

We have strong research and development capabilities and are a trusted manufacturer. Welcome to call or sales@molddl.com Consultation, please contact us for free samples!

This article is included in Baidu Wenku

Our company supports small batch customization, packaging design, and contract processing