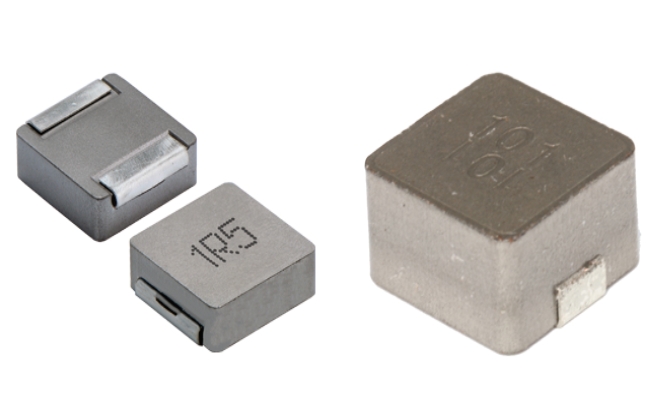

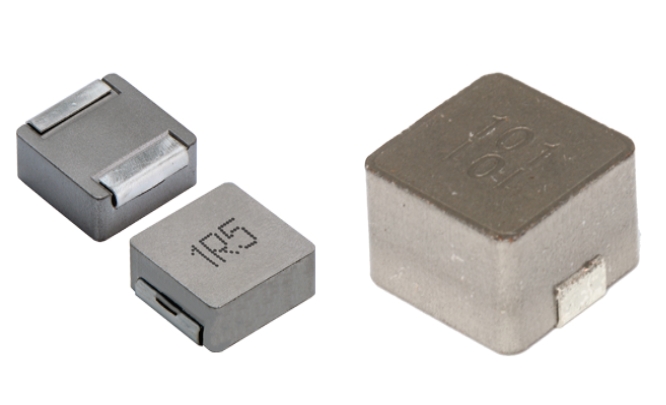

Hot pressed inductor adhesive, hot pressed adhesive process for forming inductor magnetic powder connection adhesive

Product Overview:

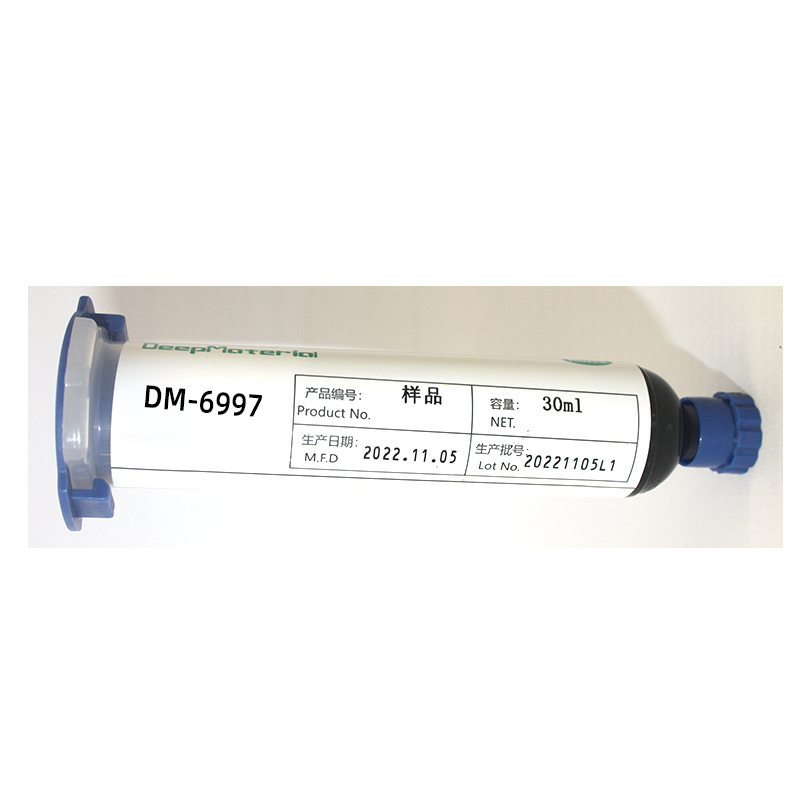

DM-6997 is a formed inductor magnetic powder connecting material used in hot pressing adhesive technology, called hot pressing inductor base adhesive. It is a two-component epoxy adhesive, where component A is a clear epoxy resin solution; Component B is a curing agent, appearing as a gray white solid in the form of flakes.

Product features:

| Technical system | epoxy resin |

| appearance | Colorless transparent colloid (A) |

| form | Two component mixing |

| Mixed mass ratio | 25:1 |

| Curing method | Heating curing |

| Product features | Excellent insulation and adhesion |

| application | Heating bonding of magnetic powder, metal, glass, aluminum, stainless steel, etc |

| index | Unit | numerical value | |

| appearance | Component A | Transparent liquid | |

| Component B | White solid | ||

| density | Component A | g/ cm³ | 1.08 |

| Component B | g/ cm³ | 1.10 | |

| density | Component A | mPa.s | 100 |

| Mixing ratio (mass ratio) | – | 25:1 | |

| Solid content | % | 50 | |

| Operation time | H | <10 | |

| Curing time | @80 | H | 1 |

| @90 | 1 | ||

| @105 | 1 | ||

| @120 | 1 | ||

| @135 | 1 | ||

| @150 | 1 | ||

| Tensile shear strength | Mpa | >8.0 | |

| Glass transition temperature (DSC) | ℃ | 115 | |

| Cracking temperature @ 5% (TGA) | ℃ | 345 | |

| Reliability testing after curing | High and low temperature storage @ -55 125 ℃ | – | 96H unchanged |

| High temperature and humidity @ 85 ℃ 85% RH | – | 96H unchanged | |

| Cold and hot shock @ -40~125 ℃ | – | 1000 cycles without change | |

| Salt spray test @ 35 ℃ 5% | – | 96H unchanged | |

| working temperature | ℃ | -40~125 | |

The place of use must be well ventilated. Component A is a homogeneous and stable solution of volatile solvents with flammable and explosive properties. During storage, it should be kept away from open flames and sunlight, and containers containing component A should not be heated. During transportation and use, handle with care and pay attention to ventilation and breathability. The storage temperature should be below 30 ℃ and sealed for storage.

Component 2B is a grayish white sheet-like solid that can be oxidized into grayish black or even brownish black solid when in contact with air. The change in color does not affect its curing properties as a curing agent. The B component has certain hazards, and the operation requires wearing protective gloves and masks. It is strictly prohibited to directly contact B agent with hands.

When using the main agent and curing agent, special equipment should be used to mix them evenly according to the specified proportion.

After adjusting the main agent and curing agent, they should be used up within the operational time

When the material comes into contact with the skin, wipe it off with a cloth and rinse the affected area with water and soap

Packaging rules: 10 KG A/B combination

Store in a cool and dry place under storage conditions below 30 ℃. The original packaging is sealed and stored in a dark place, with a validity period of 6 months

You have mentioned very interesting points!

ps decent web site.Expand blog

Thank you very much for your comment.

услуги по ремонту айфонов

أنابيب الفولاذ المقاوم للصدأ في العراق تتميز مصنع إيليت بايب كمزود رئيسي لأنابيب الفولاذ المقاوم للصدأ في العراق، معروفة بجودتها الاستثنائية وموثوقيتها. تم تصميم أنابيب الفولاذ المقاوم للصدأ لدينا لتحمل الضغوط العالية ودرجات الحرارة القصوى، مما يجعلها مناسبة لمجموعة واسعة من التطبيقات الصناعية والتجارية. يضمن استخدام المواد الممتازة وعمليات التصنيع المتقدمة أن توفر أنابيبنا قوة فائقة وطول عمر. كواحدة من الأسماء الأكثر موثوقية في الصناعة، تلتزم مصنع إيليت بايب بتقديم منتجات تفوق التوقعات. استكشف أنابيب الفولاذ المقاوم للصدأ لدينا بمزيد من التفصيل بزيارة موقعنا الإلكتروني على ElitePipe Iraq.