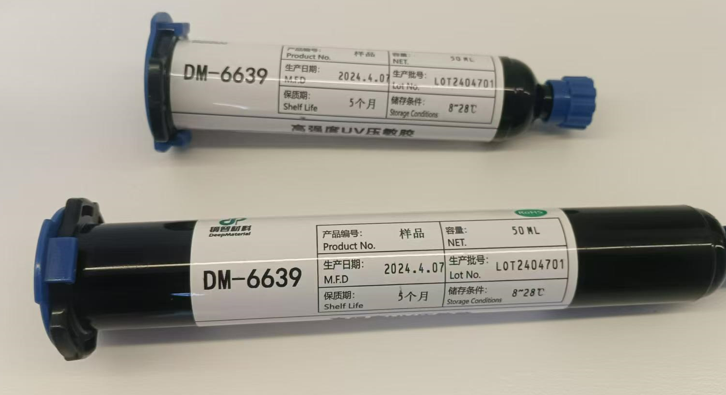

DeepMaterial DM6639 high-strength UV pressure-sensitive adhesive replaces pur adhesive

Product Overview

DM-6639 is an acrylic adhesive system. After UV curing, it has a certain degree of pressure sensitivity. This formula is based on solvent-free modified acrylic ester, with a semi transparent colloid. The adhesive surface can be quickly cured in a few seconds, and after curing, it can be attached to another substrate. After a short period of pressure holding and a period of post curing, the mechanical properties reach the best, and the product can be used as a substitute for PUR. In addition, this adhesive can accept the compression of uneven substrates, fully cure to meet IP68 waterproof requirements, and heat to a certain temperature to damage the bonding area, thereby achieving the purpose of repair.

Product information for producing high-strength UV pressure-sensitive adhesive

| Technical system | Acrylic acid |

| Appearance (uncured) | Translucent viscous liquid |

| form | Single component |

| Waterproof level | IP68 |

| Curing method | UV+post curing |

| Product Features | Room temperature dispensing, fast curing speed, short holding time |

| application | Sealing and bonding |

| storage stability | 8~28℃5 months in a sealed environment |

Performance indicators of high-strength UV pressure-sensitive adhesive products

| index | unit | numerical value |

| proportion | g/cm3 | 1.05 |

| viscosity @25℃52#5r | Cps | 60000 |

| UVCuring time @400mW/cm2LED | s | 10 |

| Opening Hours | Min | 10 |

| Initial tensile strength(PC/PC) | MPa | 1 |

| Recommended post curing time | H | 24 |

| Final tensile strength(PC/PC) | MPa | 6 |

| Final shear strength(PC/PC) | MPa | 7 |

Instructions for using high-strength UV pressure-sensitive adhesive

This product is sensitive to light and air. During storage and use, exposure to the external environment and artificial light should be minimized as much as possible.

When dispensing this product, a black rubber hose and a needle with UV protection are required. To achieve optimal performance, all surfaces in contact with the material should be clean and free from solder residue, grease, release agents, or other contaminants before material distribution.

Excessive uncured glue can be wiped off with alcohol.

After the dispensing is completed, UV curing should be carried out as soon as possible. After UV curing, the adhesive substrate should be pressed and held for a short period of time to maintain the pressed state.

The curing speed depends on the intensity of the lamp and the distance from the light source.

Precautions for high-strength UV pressure-sensitive adhesive

1 Please store away from children. This product is recommended for use in dry places.

2 If it accidentally gets on the skin, please wash it immediately with soapy water.

3 If it accidentally gets into the eyes, please wash with plenty of water first and then seek medical attention.

4 Please refer to the MSDS of this product for detailed information.

Storage conditions for high-strength UV pressure-sensitive adhesive

The packaging size is 50ml per tube, or customized according to customer needs. Sealed and stored in a dry and dark place, with a shelf life of 5 months at 8-28 ℃.

Note: the above technical parameters are only for the purpose of providing product information and environmental safety information, not for the guarantee value of product performance and quality.