How to Reduce Whitening Effect When Using Instant Adhesive in Glue Factories

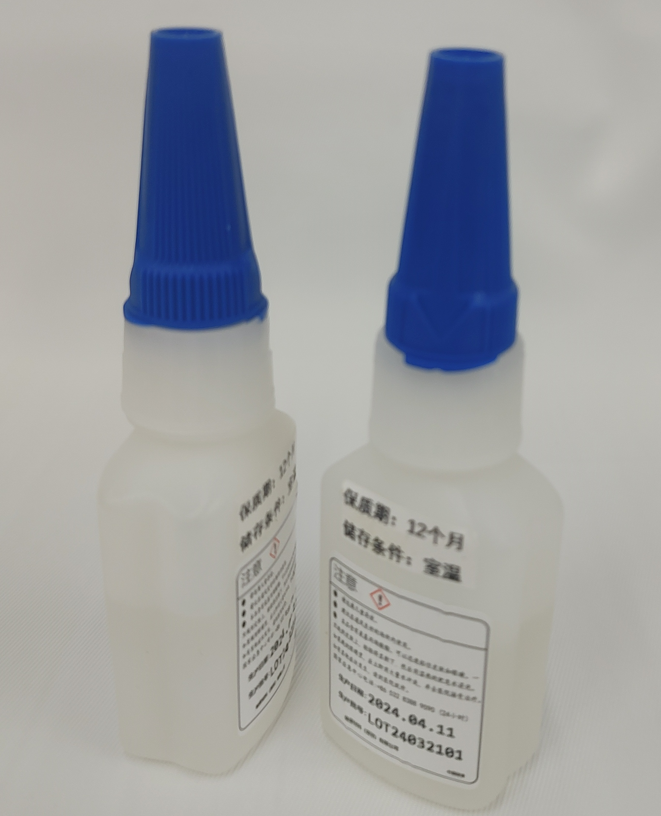

Instant adhesive, also known as instant glue or quick-drying glue, is a type of single-component, room-temperature, fast-curing adhesive made from α-cyanoacrylate. It features convenience, rapid curing speed, and strong bonding strength. To meet the diverse industrial needs, various types of instant adhesives have been developed, including general-purpose instant adhesives, fast-curing instant adhesives, impact-resistant instant adhesives, high-temperature resistant instant adhesives, low-whitening instant adhesives, and instant adhesive additives.

When using instant adhesives, a whitening phenomenon may occur, referred to in the industry as the “whitening effect.” Most instant adhesives experience some degree of whitening, and truly non-whitening instant adhesives do not exist. However, preparations can be made when selecting and using instant adhesives to minimize this effect.

Here are some methods and experiences to reduce the whitening effect during the use of instant adhesives:

1. During application, ensure the working area is as dry and ventilated as possible, and wait a while before placing glued products in plastic bags.

2. If it’s rainy during application, consider using a dehumidifier to remove moisture.

3. For high-end products, using low-whitening instant adhesives can provide noticeable effects.

4. Instant adhesive accelerators can be used to speed up the curing process and reduce whitening.

How to Reduce Whitening Effect When Using Instant Adhesive in Glue Factories

These methods can effectively reduce the extent of whitening in instant adhesives. Instant adhesives can bond materials such as glass, ceramics, rubber, silicone, metal, wires, jade, acrylic, ABS, PC, as well as electronic components and parts. We welcome everyone to choose our instant adhesive products.

We invite new and returning customers to reach out for detailed inquiries. We support small batch orders and customized appearances. We offer free 1-on-1 technical consulting services! Our R&D center covers over 3,000 square meters in the Shenzhen Guangming pilot industry base and contains more than 12 laboratories. We encourage all customers to contact us for consultations. Our strong R&D capabilities make us a trustworthy manufacturer. For inquiries, please call or email sales@molddl.com. Contact us for free samples!

This article is included in Baidu Wenku, and our company supports small batch customization, packaging design, and contract manufacturing.