Overview of Automotive Inductive Adhesive Products

DM-6982 is a molding magnetic powder connector material used for cold hot pressing universal bonding process, called universal inductor base adhesive. It is a two-component epoxy adhesive, in which component A is a brown epoxy resin solution; Component B is a curing agent that appears as a white flake solid.

Characteristics of automotive grade inductor adhesive products

| Technical system | epoxy resin |

| appearance | Brown transparent liquid (A) |

| form | Two-component mixture |

| Mixing quality ratio | 25:1 |

| Curing method | Heating solidification |

| Product Features | Excellent insulation, excellent adhesion, and a certain degree of toughness at high temperatures |

| application | Heating bonding of magnetic powder, metal, glass, aluminum, stainless steel, etc |

Physical properties of automotive grade inductor adhesive

| index | unit | numerical value | |

| appearance | Component A | / | Brown transparent liquid |

| Component B | / | White flakes | |

| density | Component A | g/ cm3 | 1.081 |

| Component B | g/ cm3 | 1.139 | |

| viscosity | Component A | mPa.s | 15 |

| Mixing ratio (mass ratio) | – | 20:1 | |

| Solid content | % | 50 | |

| Operation time | H | <10 | |

| Curing time@170 | H | 2 | |

| Tensile shear strength(SUS) | Mpa | >8.0 | |

| Glass transition temperature(DSC) | ℃ | 155-165 | |

| Cracking temperature5%Loss(TGA) | ℃ | >37 0 | |

| Reliability testing after solidification | High and low temperature storage@-55 125℃ | – | 96Hunchanged |

| High temperature and high humidity@85℃85%RH | – | 96Hunchanged | |

| Thermal Shock@-40~ 125℃ | – | 1000cycles unchanged | |

| Salt spray test@35℃ 5% | – | 96Hunchanged | |

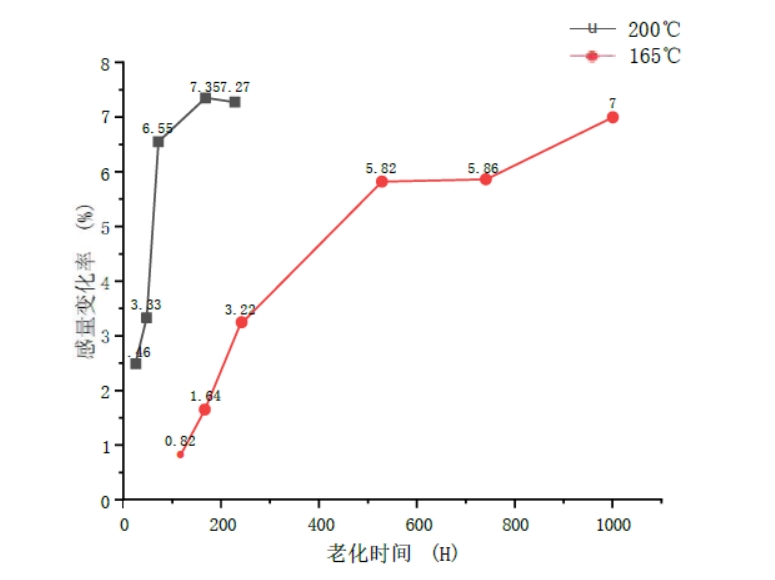

Typical inductance aging test of automotive grade inductor adhesive shows changes in inductance

Precautions for Automotive Inductive Adhesive

- The place of use must have good ventilation. 2 Component A is a homogeneous and stable solution of volatile solvents, with flammable and explosive properties. During storage, it should be kept away from open flames and direct sunlight, and containers containing component A should not be heated.

During transportation and use, handle with care and pay attention to ventilation and air permeability. The storage temperature should be below 30 ℃ and sealed for storage. - Component B is a grayish white sheet-like solid that can be oxidized to a grayish black or even brownish black solid upon contact with air. The change in color does not affect its curing properties as a curing agent. The B component has certain hazards, and the operation requires wearing protective gloves and masks. It is strictly prohibited to directly touch the B agent with hands.

- When using the main agent and curing agent, specialized equipment should be used to mix them evenly according to the specified ratio.

- After adjusting the main agent and curing agent, they should be used up within the operable time.

When the material comes into contact with the skin, wipe it off with a cloth and rinse the affected area with water and soap.

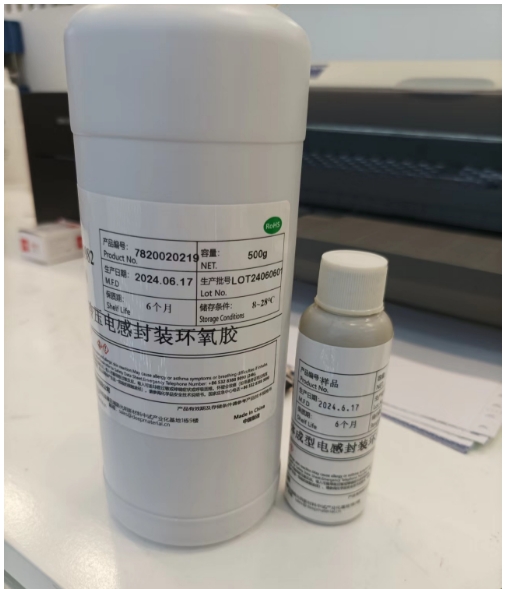

Automotive standard inductor adhesive packaging

Packaging rules: 10 KG A/B combination

Storage conditions for automotive grade inductor adhesive

Store in a cool and dry place below 30 ℃ in the original packaging, sealed and protected from light, with a shelf life of 6 months