What structural adhesive is better for bonding stainless steel and metal by glue manufacturers

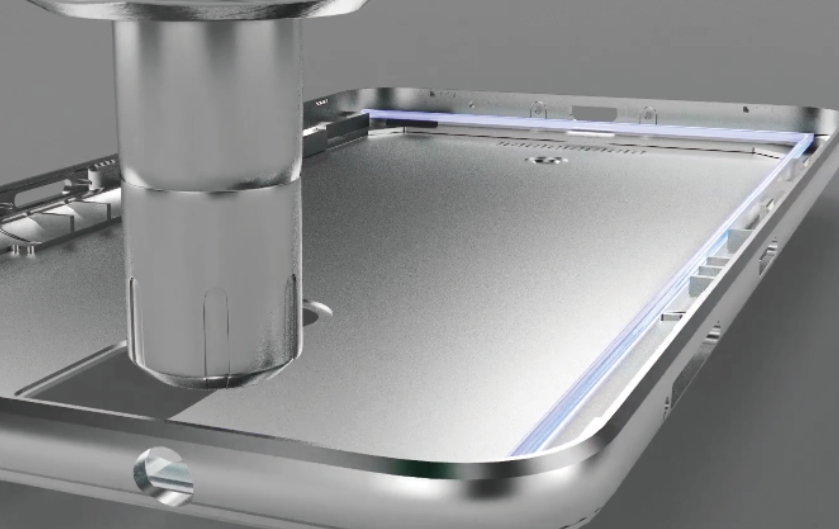

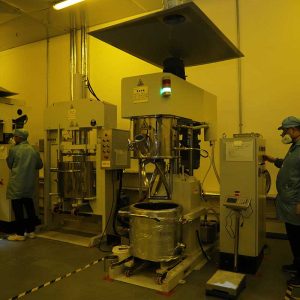

The use of DM metal adhesive is very suitable for bonding stainless steel and metal. This adhesive has the characteristics of high bonding strength, temperature resistance and waterproofing, stable performance, and is not easy to peel off. The main component of metal adhesive is ethyl cyanoacrylate, which is a type of adhesive with strong bonding force, suitable for rapid bonding of various metals, plastics, rubber, jewelry, electronic products, etc. Easy to operate, can be manually operated or used with a dispensing machine, suitable for continuous production line operations.

When choosing to bond metals, different types of metal adhesives can be selected according to the needs. For large-area bonding of metals, high-strength adhesives such as Ergo1307, DM1925, DM1665, and DM1610 can be chosen as alternatives to some welding methods. For small area bonding of metals, metal quick drying adhesives such as DM5923, DM5634, etc. can be used. Please note that the selection of metal adhesives mentioned above is for reference only, and should be based on actual usage needs and the advice of the adhesive engineer.

Regarding the bonding between electroplated metals, electroplated metal parts can be bonded. You can consult and obtain samples for testing. For the bonding of small area electroplated metal and stainless steel, metal quick drying adhesive can be used. This single component, transparent color, low viscosity, high viscosity adhesive is specifically used for bonding between metals. It has the characteristics of strong adhesion, stable performance, low whitening, and fast positioning, and has a certain degree of waterproofing. It can reach the strength of use in half an hour, with fast curing and high efficiency. This glue has passed ROHS, REACH and other certifications, with patented packaging design, easy operation, and saves glue.

When bonding small areas of stainless steel, the following precautions should be taken:

1. Check whether there are impurities such as paint, ink, rust, dust, rust proof oil, release agent, etc. on the surface of stainless steel. If there are any, clean them thoroughly and dry them before applying glue;

2. The smoothness of the stainless steel surface has an impact on the bonding strength of the metal instant adhesive. The smooth surface can be roughened, cleaned, and dried before applying the adhesive;

3. When using metal quick drying adhesive, avoid wearing woven gloves for dispensing to prevent reactions from generating heat and burning the skin. At the same time, maintain good ventilation in the operating area to eliminate odors.

Adhesive manufacturers, DM metal adhesive is an ideal choice for bonding metals, with a wide range of applications and reliable performance, which can improve production efficiency and ensure bonding quality. During use, it is necessary to strictly follow the operating procedures to ensure safe and efficient completion of the bonding task.