Will the LED three proof adhesive (three proof paint) process corrode the LED light board and LED beads?

Three proof adhesive manufacturer is a technology-based company that mainly produces semiconductor packaging, display packaging materials and electronic adhesives, optical grade and electronic grade resins. It focuses on providing packaging and adhesive materials and solutions for semiconductor and electronic component packaging enterprises, new display and consumer electronics enterprises, and solving customers’ key material domestic substitution needs in packaging materials, precision process protection, high-precision bonding, electrical performance protection, optical display applications, etc.

Many customers who produce LED lighting products ask the sales personnel of the three proof adhesive manufacturer if there are three proof paint products suitable for protecting LED light boards and LED beads. The customer also emphasizes whether your three proof paint will corrode LED light boards and LED beads? The sales engineer of the three proof adhesive manufacturer knows that this type of customer is quite concerned and attaches great importance to this issue. Because if the three proof paint is corrosive, it will cause significant damage to related products, thereby affecting the overall effect of the product. The three proof adhesive manufacturer strictly controls the research and development, raw material selection, production process, and finished product testing of LED three proof paint, and solemnly guarantees that every shipment of LED three proof paint from the three proof adhesive manufacturer is qualified and safe. Three proof paint will not corrode LED light boards and LED beads, nor will it affect the luminous effect of LED beads. With LED products protected by three proof paint, the stability and reliability of the products will be greatly improved.

Will the LED three proof adhesive (three proof paint) process corrode the LED light board and LED beads?

Due to the harsh usage environment and high standards for moisture and waterproof performance, LED products have very strict requirements for the three proof paint on LED displays, especially in the northern region where there is a large temperature difference between day and night, which greatly tests the high and low temperature resistance and moisture resistance of the three proof paint. When used outdoors, environmental factors such as salt spray and ultraviolet radiation should also be considered. In addition to multiple protections, good circuit stability and safety should be maintained. The 160, 161, and 170 models from three proof adhesive manufacturers are suitable for LED products, and their stability has been widely praised by users.

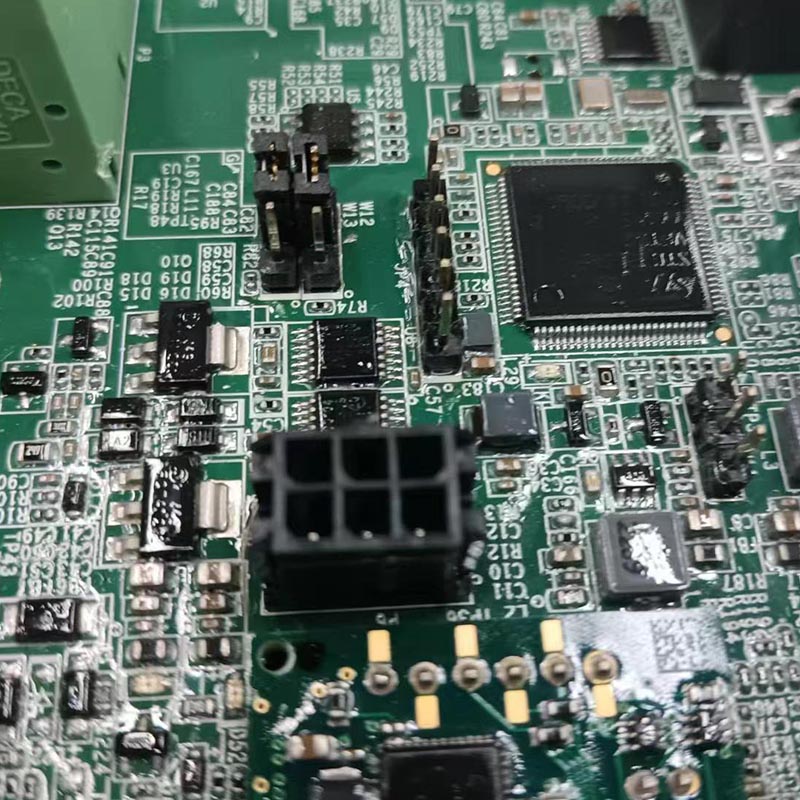

Three proof adhesive manufacturers apply LED three proof paint to LED outdoor display screens, LED lighting fixtures, radar control systems, power equipment, communication equipment, LED street lights, LED power supplies, traffic signals, outdoor cameras, outdoor instruments, etc.

Will the LED three proof adhesive (three proof paint) process corrode the LED light board and LED beads?

Three proof adhesive manufacturers offer a variety of models to choose from, with stable quality and timely supply, making them a long-term reliable partner for our customers. For more information on three proof paint products and technical information from three proof glue manufacturers, please visit their official website www.aicarder.com. Three proof glue manufacturers provide you with professional and comprehensive technical support and product guidance for three proof paint and various adhesives.

Three proof paint, also known as circuit board three proof paint, three proof adhesive, insulation paint, moisture-proof paint, covering adhesive, coating adhesive, moisture-proof oil, common film coating, conformal coating, electronic coating material, etc., the English name is normal coating. Three proof paint is a type of single component transparent or semi transparent adhesive that can be cured at room temperature, by heating, or by ultraviolet light. It has the characteristics of low viscosity, high transparency, excellent insulation performance, high and low temperature resistance, and easy use. Three proof paint is mainly used for covering and coating the surface of various assembled electronic circuit boards, providing protection for the circuit boards and achieving multiple protections such as moisture-proof, anti fouling, anti salt spray, insulation, etc., in order to improve product performance, stability, safety, and service life. It can also be used for shallow encapsulation and filling of electronic products.